High-Speed Temperature Measurement - Fast response time

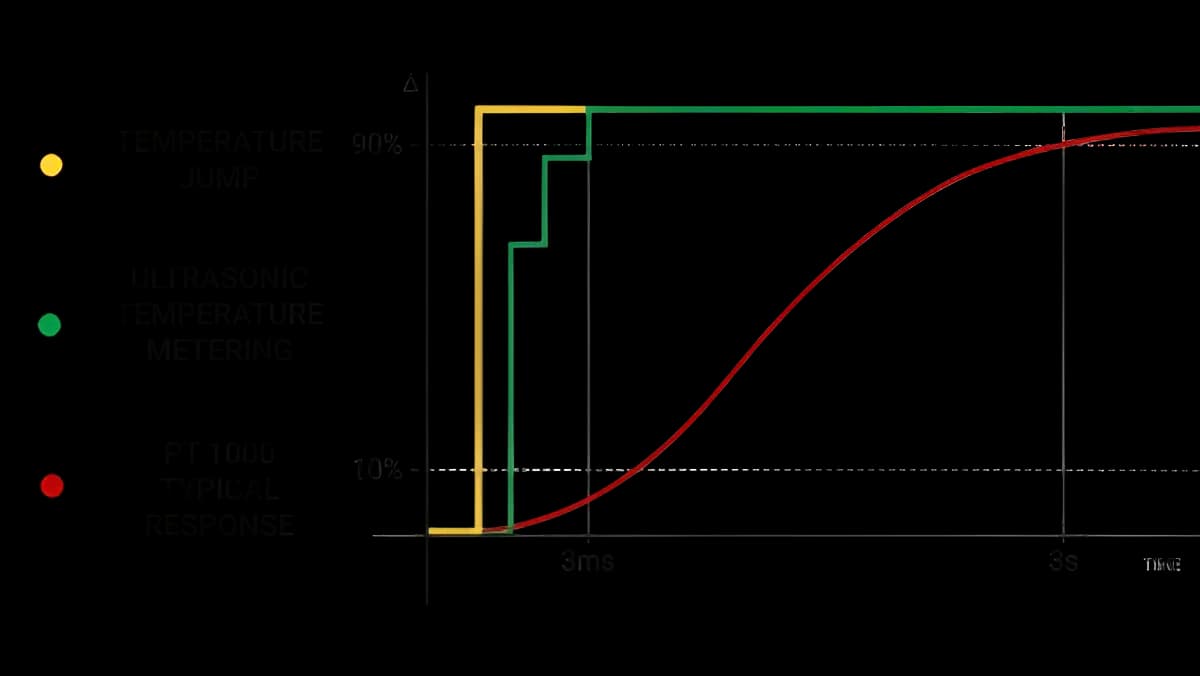

Fast response time allows temperature measurement through ultrasonic technology, delivering accurate readings within milliseconds. The non-intrusive method eliminates contact with the measured medium. It proves suitable for harsh environments including extreme temperatures, corrosive substances, and high-pressure systems.

Temperature Measurement with Ultrasound

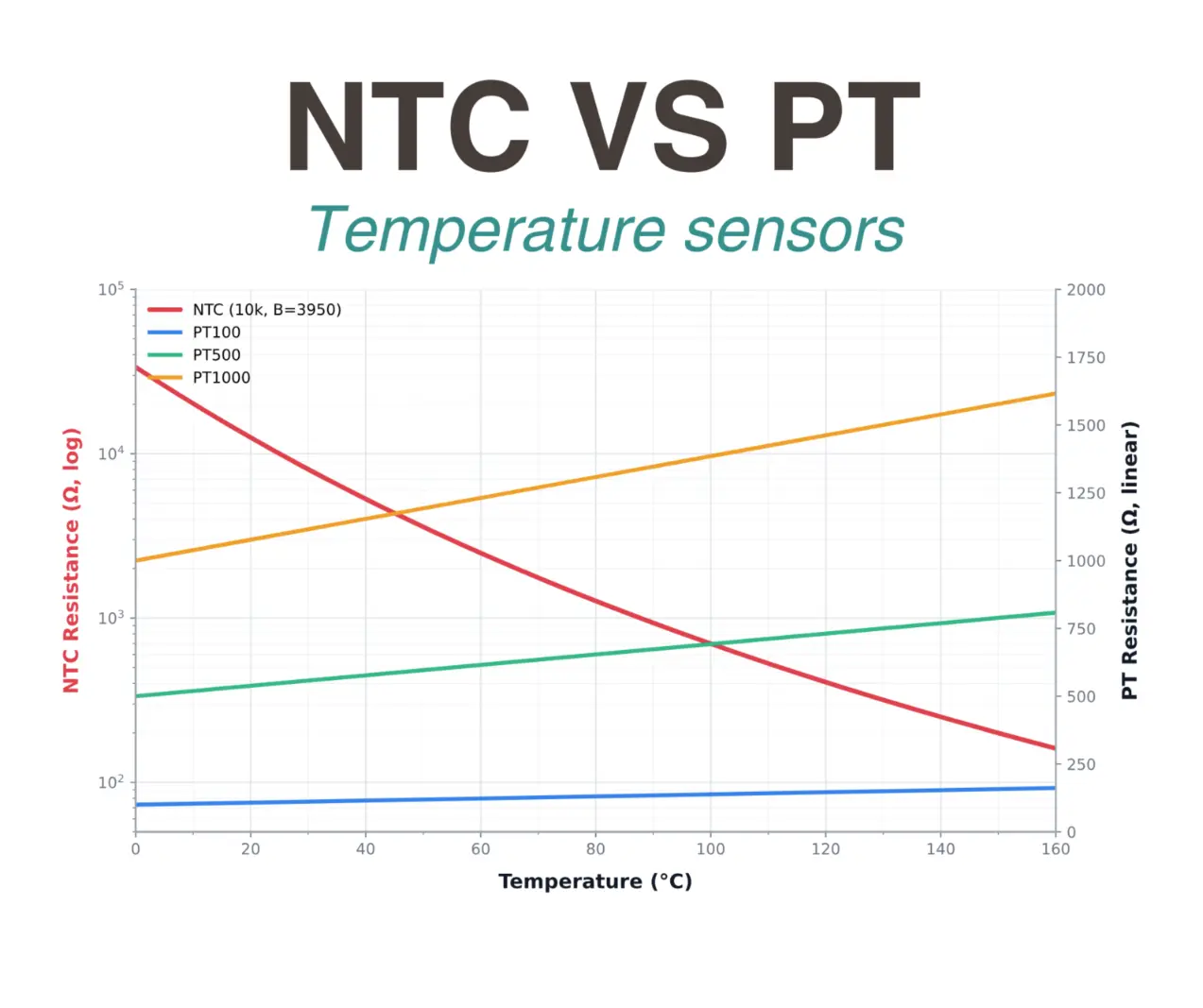

In sensorics, measuring the temperature of the working liquid or gas is essential for understanding and controlling any process. In the market many types of temperature sensors can be found and are being used.

The most common types are NTC type of temperature sensors or PT type temperature sensors. However, besides directly measuring the temperature with a temperature probe, there are also other ways of measuring the temperature of a fluid or a gas.

In Ultrasonic Flow Metering, the speed of sound is a measured by-product of the measurement. The speed of sound of any fluid changes with a change in temperature.

How can I read the temperature directly from the speed of sound?

Based on the specific speed of sound measured by the ultrasonic flow sensor and the liquid properties that flows through the sensor a correlation look-up table can be made.

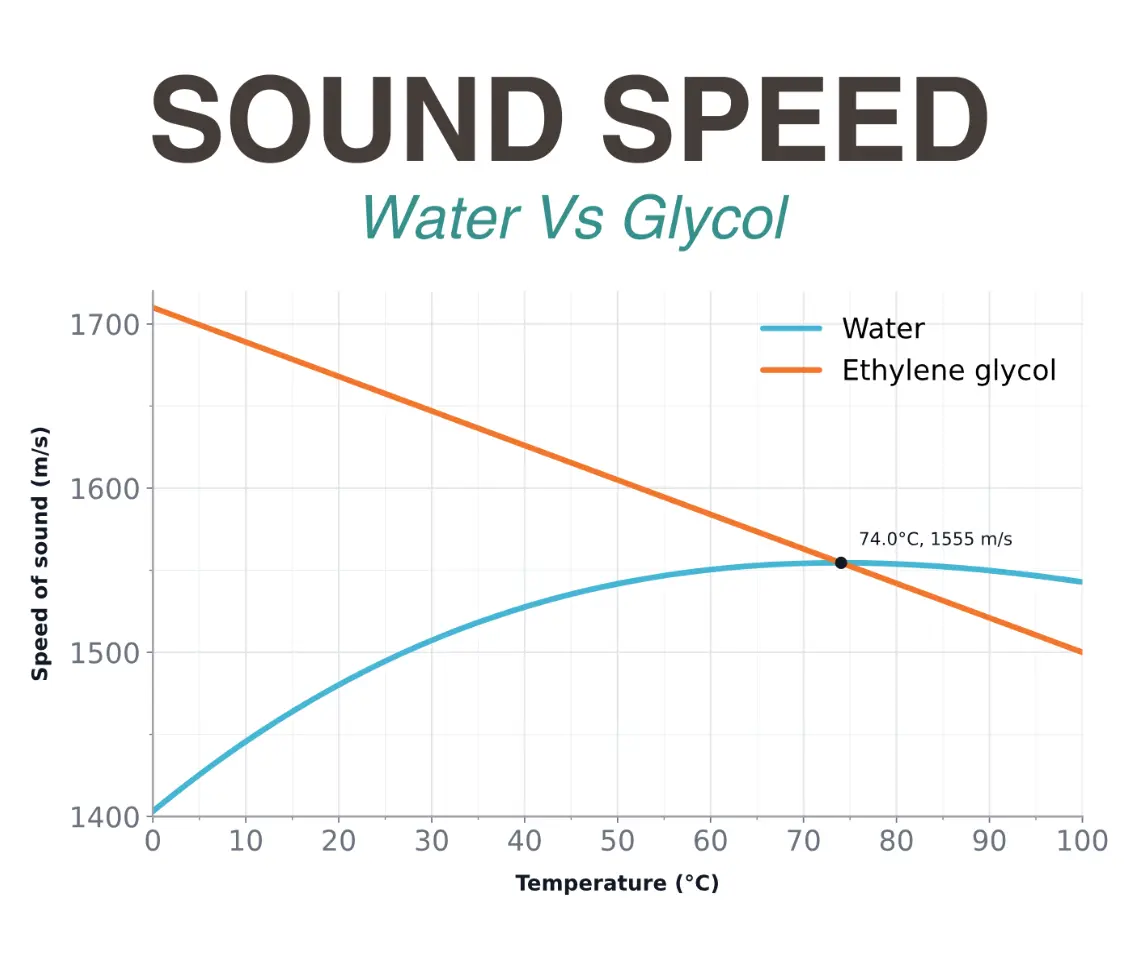

For example Water or water-based liquids do have a specific anomality which is related to the bulk modulus that increases at the cold temperatures (becoming less compressible) but starts decreasing above 60°C (becoming more compressible).

In practical words this means that the speed of sound reaches its peak at 70°C and then decreases despite temperature increase or decrease, making it very difficult to determine the temperature for applications with large temperature operation domain (e.g. 0 – 100 °C).

To overcome the challenges of special water behavior, a back-up temperature sensor, such as a PT1000 is used to correct for any ambiguity in the measurement.

For most of the other common liquids (anti-freezers, fuels, oils) the temperature/speed of sound relation is rather linear, and the correlation works in a much wider temperature domain, in some cases being able to completely remove the physical temperature measurement element from the flow meter.

As the speed of sound changes instantly with the measurement frequency of the flow meter, makes it one of the fastest temperature measurement methods in the market. We are talking here about microseconds . This advantage is a key feature for ultra fast processes where quick reactions regarding temperature and regulation are essential.