Industries

Expert support backed by over 40 years of combined experience in precision flow measurement and sensor technology.

Agriculture

Reliable flow monitoring for irrigation systems, liquid fertilizers, and agricultural processing equipment.

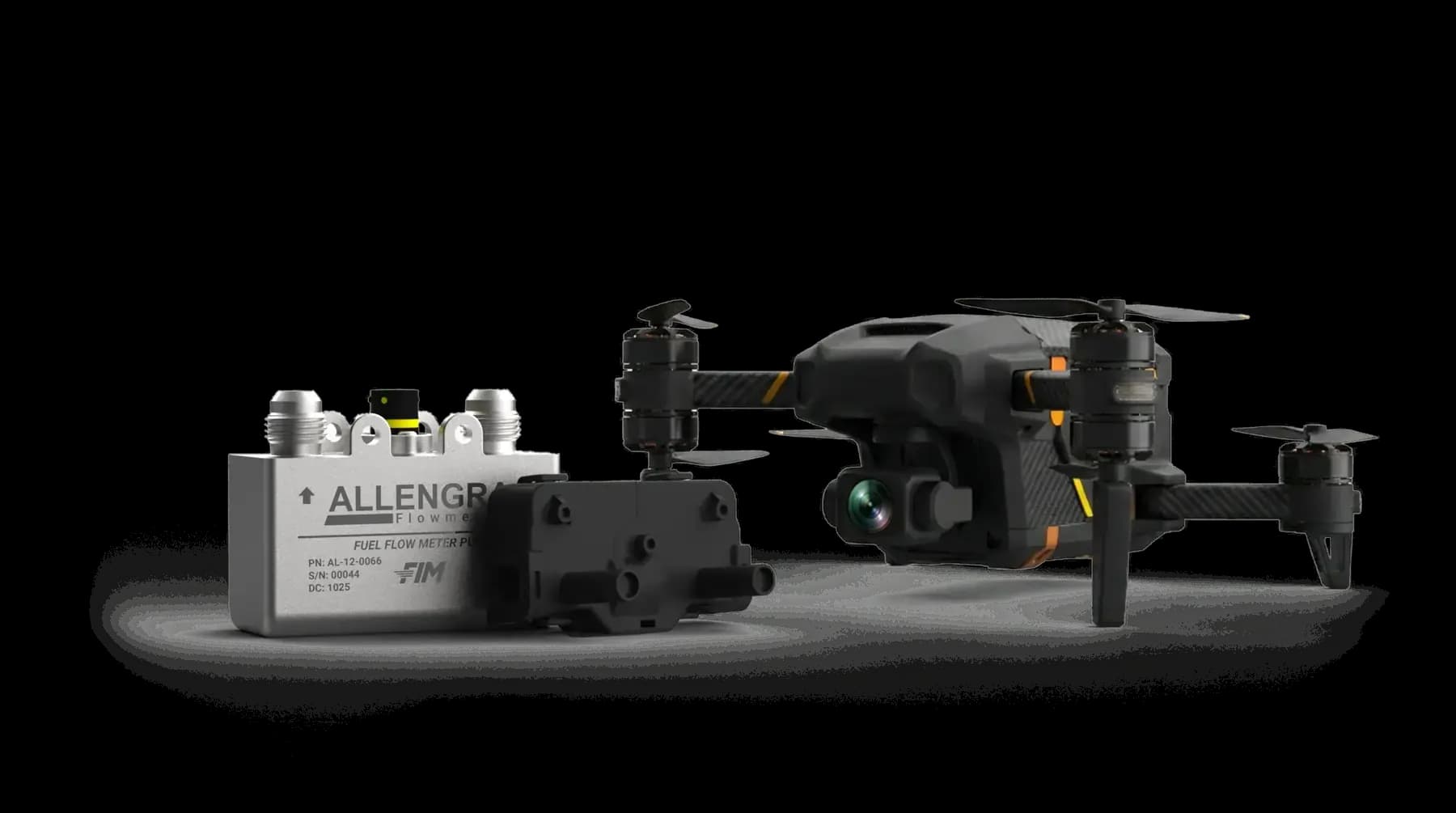

Hydrogen

Advanced ultrasonic flow measurement solutions for hydrogen fuel cells and mobility applications. Non-intrusive technology ensures precise monitoring, optimal system performance, and long-term reliability without compromising safety in hydrogen environments.

Cooling

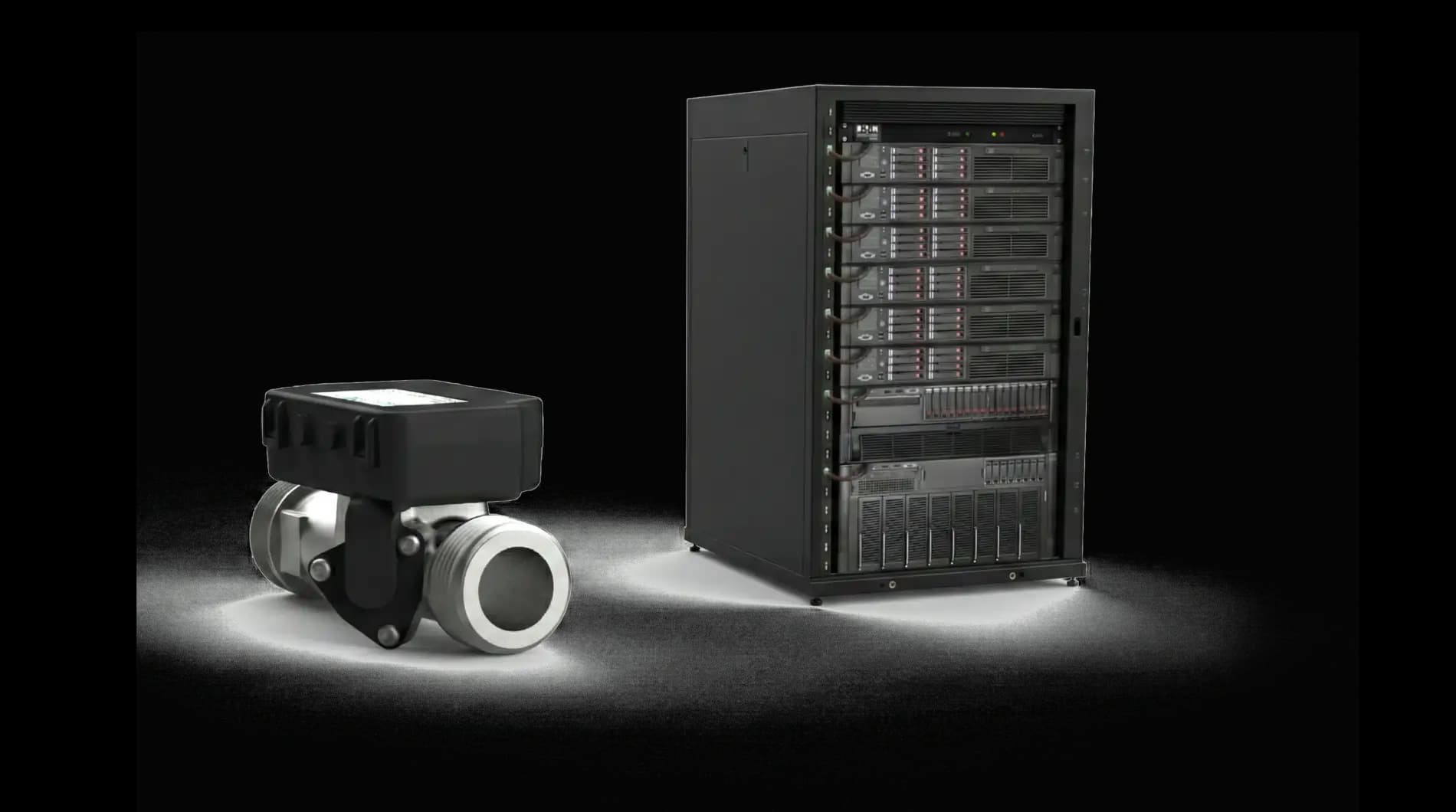

Precision ultrasonic flow monitoring for industrial cooling applications such as plastic injection molding temperature control, automotive cooling circuits, and semiconductor production facilities. Non-invasive technology with minimal pressure drop, gas bubble detection, and high-temperature capability up to 220°C ensures optimal thermal management, energy efficiency, and reliable operation across demanding industrial environments.

KNOWLEDGE BASE

Allengra sensors are deployed across HVAC systems, hydrogen fuel cell vehicles, industrial process control, medical equipment, and energy management applications. OEM partners integrate our technology into heat pumps, cooling systems, fuel dispensers, and analytical instruments where precision liquid measurement is critical. We serve sectors ranging from automotive and aerospace to building automation and renewable energy infrastructure.

Yes. Our ultrasonic technology is well-suited for hydrogen carrier fluids, ammonia solutions, and other alternative energy media due to its material compatibility and non-contact measurement principle. We collaborate with hydrogen mobility and power-to-X developers to validate sensor performance against emerging fuel standards. Specific sensor variants are available for cryogenic, high-purity, or corrosive fluid applications.

Absolutely. We work closely with OEM partners to adapt housing designs, optimize flow body geometry, adjust output formats, and develop application-specific firmware. High-volume programs can include custom calibration profiles, private labeling, and co-development of integrated flow modules. Our engineering team supports customers from concept through production to ensure seamless product fit.

Allengra sensors are designed and tested to meet automotive and aerospace vibration standards, including random, sinusoidal, and shock profiles typical of mobile platforms. Our robust mechanical design and advanced signal processing maintain measurement accuracy and reliability under continuous dynamic stress. Validation testing includes long-term durability assessments to ensure performance retention over the product lifecycle.

Yes. Allengra provides comprehensive technical support including integration guidelines, reference implementations, and direct engineering consultation for industrial automation and process control deployments. We assist with system architecture planning, communication protocol configuration, and field commissioning support. For enterprise customers, we offer training programs and long-term partnership agreements to ensure successful scalability.