Technologies

Advanced Ultrasonic Solutions for Precision Flow Measurement

At Allengra, we pioneer ultrasonic sensing technology that transforms how industries measure, monitor, and control fluid flow. Our non-invasive ultrasonic solutions deliver unparalleled accuracy across liquids and gases, eliminating the limitations of traditional mechanical meters while providing superior performance in the most demanding applications.

Built on the time-of-flight principle, our ultrasonic transducers measure fluid velocity by analyzing the transit time difference of acoustic pulses traveling upstream and downstream. This contactless approach ensures zero pressure drop, immunity to magnetic interference, and exceptional reliability—independent of pressure, density, or electrical conductivity.

Ultrasonic Principle - Time-of-flight Principle

Gas Bubble Detection - Technology

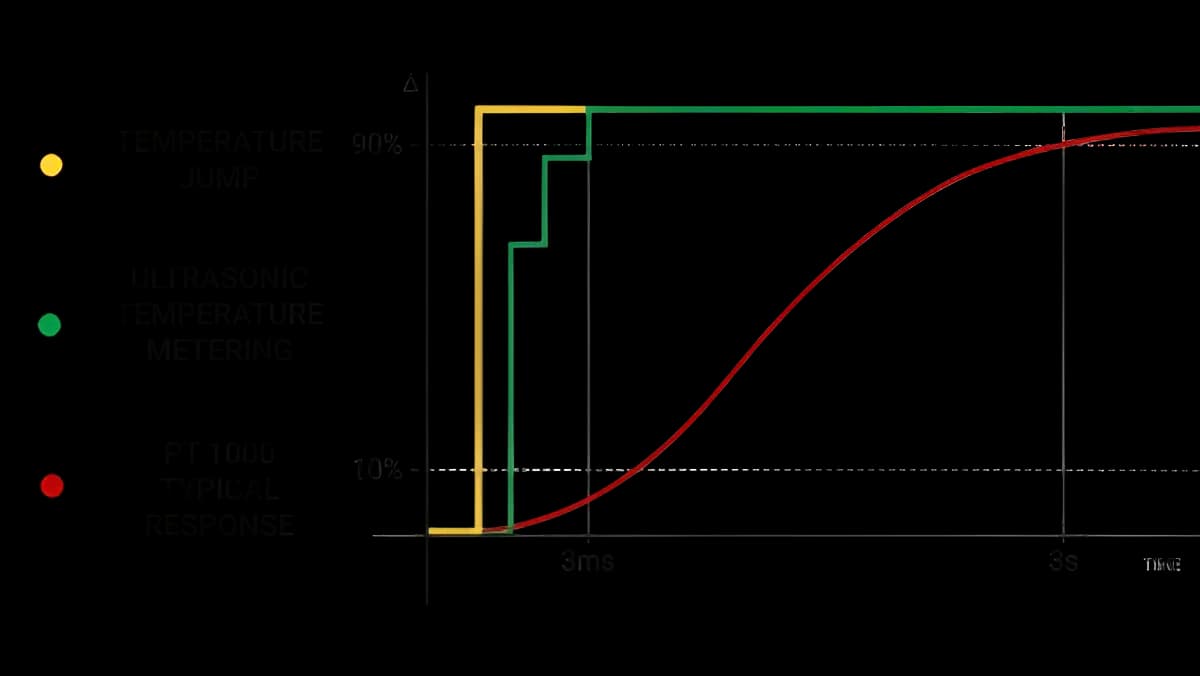

High-Speed Temperature Measurement - Fast response time

Glycol Concentration - Glycol concentration detection and freezing-point estimation

Fluid Analysis - Fluid Identification

Gas Concentration - Gas Concentration Measurement

KNOWLEDGE BASE

Ultrasonic time-of-flight measurement sends acoustic pulses between two transducers positioned at an angle to the flow. Transit time difference between upstream and downstream pulses is proportional to fluid velocity, enabling precise flow rate calculation. This principle is independent of pressure, density, or conductivity, making it applicable to clean liquids. Integrated temperature compensation maintains accuracy across thermal operating ranges.

Ultrasonic sensors provide excellent turndown ratios, low-pressure drop, and immunity to magnetic or electrical interference unlike electromagnetic or vortex meters. Absence of moving parts eliminates maintenance, extends service intervals, and reduces total cost of ownership versus mechanical meters. Ultrasonic technology offers superior performance in bidirectional and low-flow applications where other methods struggle with accuracy or repeatability.

Ultrasonic sensors offer superior low-flow sensitivity and wider turndown ratios compared to vortex meters, which require minimum Reynolds numbers to generate stable vortex shedding. Unlike vortex technology, ultrasonic measurement introduces zero pressure drop and is immune to vibration-induced noise that can compromise vortex meter accuracy. The absence of flow obstructions also makes ultrasonic sensors ideal for viscous fluids and applications where minimal flow disturbance is critical.

Ultrasonic sensors offer superior low-flow sensitivity and wider turndown ratios than vortex meters, which require minimum Reynolds numbers for stable vortex shedding. Unlike vortex technology, ultrasonic measurement has zero pressure drop and immunity to vibration-induced noise. Absence of flow obstructions makes ultrasonic sensors ideal for viscous fluids and applications requiring minimal flow disturbance.

Our signal processing algorithms incorporate advanced filtering, multi-path averaging, and real-time temperature compensation to reject environmental noise and mechanical interference. Sensor housings are mechanically isolated and designed to minimize vibration coupling into the acoustic path. Extensive testing across automotive and industrial vibration profiles ensures that measurement accuracy remains within specification even under harsh dynamic conditions.